Products

0086-379-63939358

Semi-friable Fused Alumina is produced by fusion of very special bauxite and Bayer-alumina with additive minerals in an electric arc furnace,The pure alumina content give higher hardness crystal compare with regular brown and the additive minerals content give higher toughness compare with white and pink.So that ASF is endued excellent cutting performance with durable tool life.

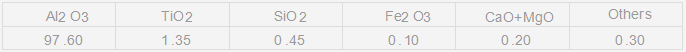

Chemical composition%(Grit 46)

Particle size distribution

F8–F1200 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

Bulk Density(g/cm3)

Blocky shape and sharp shape are also available under customer special requirements.

For purpose of improve fracture resistance of grains,semi-friable fused alumina can be calcined at1050 centigrade.At this temperature the grains internal micro-crack could be recovered and internalstress could be released as well as the hydrophily improved,so that the wheel become more longlasting tool life.

We symbol this treatment as“C1050”.

For purpose of high stress working conditions,semi-friable fused alumina can be heat treated at 1350 centigrade(open annealed),thereafter the color change from light brown to light blue.This treatment could renovate most of crystal imperfection and modify the crystal lattice with foreign oxides.Then the grains are impacted both higher cutting quality and tool life.

We symbol this treatment as“HT”.

For purpose of improve the bonding behavior of grains,semi-friable fused alumina can be modified the surface by ceramic coating.Thereafter,the coating will create a ligament between grains and resin.Meantime,the heat treated during process could also modify the crystal to increase the toughness of the grains.

We symbol this treatment as“CC”.