Silicon carbide

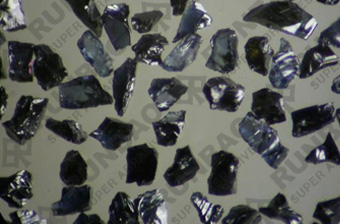

SiC is produced by the reaction of quartz sand and a carbon carrier in the electric resistance furnace.The CF10 are carefully selected the most compact crystal structure SiC roll near the core.

After perfect acid treatment and water washing after crushing,the free carbon content and iron content of grains are reduced to minimum then the shining pure crystal is imparted.CF10 has blocky grain shape with very sharp cutting edges,could apply to cutoff wheel,grinding wheel and abrasive stone for working on plastic,stone,ceramic,glass and nonferrous metals.

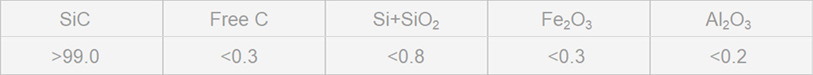

Chemical composition%(Grit 46)

Particle size distribution

F8–F1200 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

Green SiC is produced by the reaction of quartz sand and a carbon carrier with additive salts in the electric resistance furnace. The GCF10 are carefully selected the most compact crystal structure Sic roll near the core. After perfect acid treatment and water washing after crushing, the free carbon content and iron content of grains are reduced to minimum then the shining pure green color crystal is imparted. GCF10 has blocky grains shape with very sharp cutting edges, could apply to grinding wheel and honing stone for working on plastic, stone, ceramic, glass and nonferrous metals.